Products in this catalogue

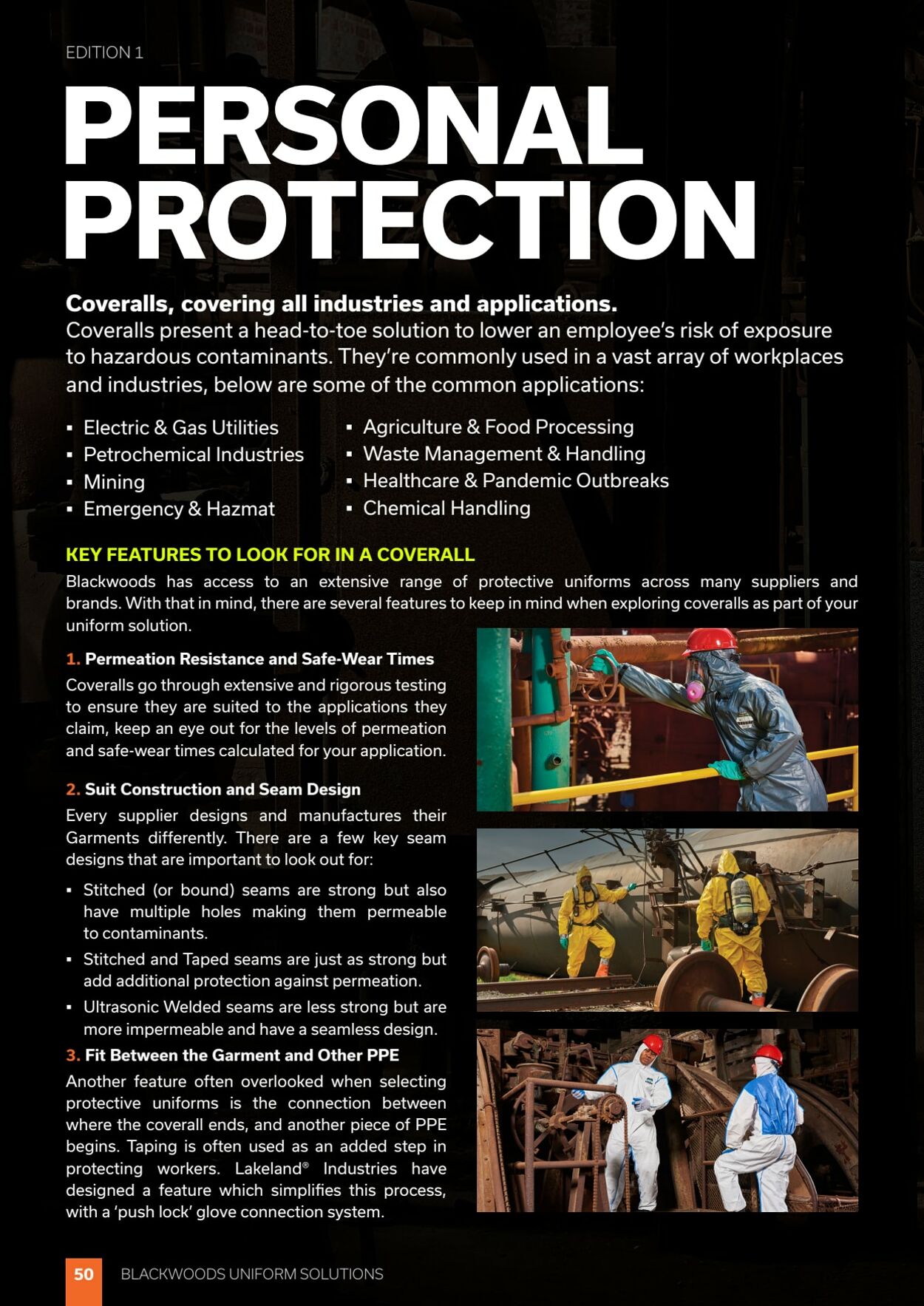

EDITION 1 PERSONAL PROTECTION Coveralls, covering all industries and applications. Coveralls present a head-to-toe solution to lower an employee's risk of exposure to hazardous contaminants. They're commonly used in a vast array of workplaces and industries, below are some of the common applications: = Electric & Gas Utilities » Agriculture & Food Processing » Petrochemical Industries = Waste Management & Handling * Mining = Healthcare & Pandemic Outbreaks = Emergency & Hazmat * Chemical Handling KEY FEATURES TO LOOK FOR IN A COVERALL Blackwoods has access to an extensive range of protective uniforms across many suppliers and brands. With that in mind, there are several features to keep in mind when exploring coveralls as part of your uniform solution. 1. Permeation Resistance and Safe-Wear Times Coveralls go through extensive and rigorous testing to ensure they are suited to the applications they claim, keep an eye out for the levels of permeation and safe-wear times calculated for your application. 2. Suit Construction and Seam Design Every supplier designs and manufactures their Garments differently. There are a few key seam designs that are important to look out for: « Stitched (or bound) seams are strong but also have multiple holes making them permeable to contaminants. = Stitched and Taped seams are just as strong but add additional protection against permeation. = Ultrasonic Welded seams are less strong but are more impermeable and have a seamless design. 3. Fit Between the Garment and Other PPE Another feature often overlooked when selecting protective uniforms is the connection between where the coverall ends, and another piece of PPE begins. Taping is often used as an added step in protecting workers. Lakeland® Industries have designed a feature which simplifies this process, with a ‘push lock’ glove connection system. | BLACKWOODS UNIFORM SOLUTIONS

| Name | Details |

|---|