Products in this catalogue

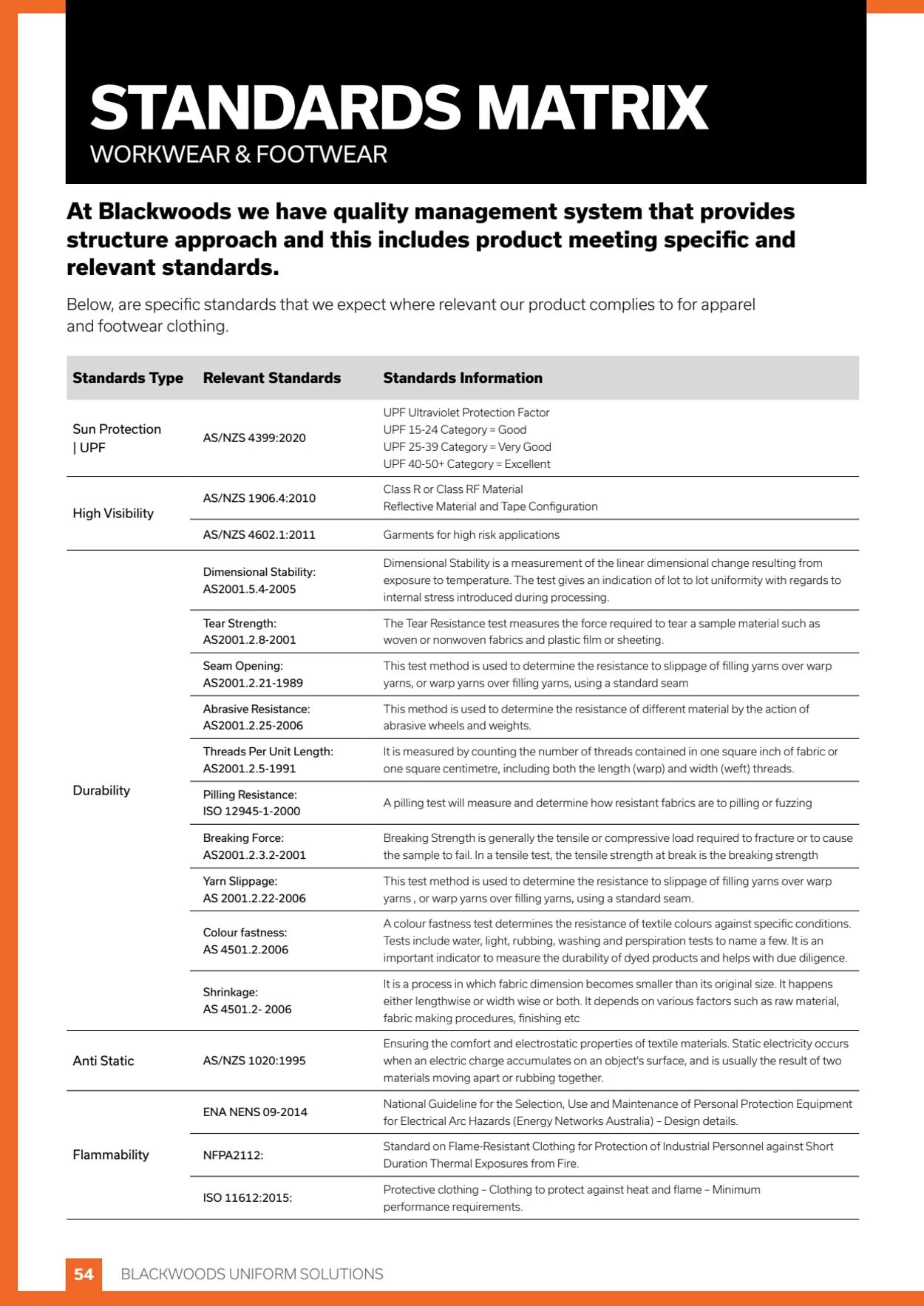

STANDARDS MATRIX WORKWEAR & FOOTWEAR At Blackwoods we have quality management system that provides structure approach and this includes product meeting specific and relevant standards. Below, are specific standards that we expect where relevant our product complies to for apparel and footwear clothing. Standards Type Relevant Standards Standards Information UPF Ultraviolet Protection Factor i PF 15-24 = Sun Protection AS/NZS 4399:2020 UPF 15-2: Category Good | UPF UPF 25-39 Category = Very Good UPF 40-50+ Category = Excellent Class R or Class RF Material AS/NZS 1906.4:201 High Visibility aaa Reflective Material and Tape Configuration AS/NZS 4602.1:2011 Garments for high risk applications Dimensional Stability is a measurement of the linear dimensional change resulting from Dimensional Stability: exposure to temperature. The test gives an indication of lot to lot uniformity with regards to AS2001.5.4-2005 internal stress introduced during processing. Tear Strength: The Tear Resistance test measures the force required to tear a sample material such as AS2001.2.8-2001 woven or nonwoven fabrics and plastic film or sheeting Seam Opening: This test method is used to determine the resistance to slippage of filling yarns over warp AS2001.2.21-1989 yarns, or warp yarns over filling yarns, using a standard seam Abrasive Resistance: This method is used to determine the resistance of different material by the action of ‘AS2001.2.25-2006 abrasive wheels and weights. Threads Per Unit Length: Itis measured by counting the number of threads contained in one square inch of fabric or AS2001.2.5-1991 one square centimetre, including both the length (warp) and width (weft) threads Durability Pilling Resistance: 65 La5te 45000 Apilling test will measure and determine how resistant fabrics are to pilling or fuzzing Breaking Force: Breaking Strength is generally the tensile or compressive load required to fracture or to cause AS2001.2.3.2-2001 the sample to fail. In a tensile test, the tensile strength at break is the breaking strength Yarn Slippage: This test method is used to determine the resistance to slippage of filling yarns over warp AS 2001.2.22-2006 yarns , or warp yarns over filling yarns, using a standard seam. A colour fastness test determines the resistance of textile colours against specific conditions. Tests include water, light, rubbing, washing and perspiration tests to name a few. Itis an important indicator to measure the durability of dyed products and helps with due diligence. Colour fastness: AS 4501.2.2006 Itis a process in which fabric dimension becomes smaller than its original size. It happens Shrinkage: "Asasotos2006 either lengthwise or width wise or both. It depends on various factors such as raw material, fabric making procedures, finishing etc Ensuring the comfort and electrostatic properties of textile materials. Static electricity occurs Anti Static AS/NZS 1020:1995 when an electric charge accumulates on an object's surface, and is usually the result of two materials moving apart or rubbing together. National Guideline for the Selection, Use and Maintenance of Personal Protection Equipment for Electrical Arc Hazards (Energy Networks Australia) - Design details. ENA NENS 09-2014 Standard on Flame-Resistant Clothing for Protection of Industrial Personnel against Short Flammabili NFPA: : ammabiny a Duration Thermal Exposures from Fire Protective clothing - Clothing to protect against heat and flame - Minimum performance requirements. ISO 11612:2015: KWOOD!

| Name | Details |

|---|