Products in this catalogue

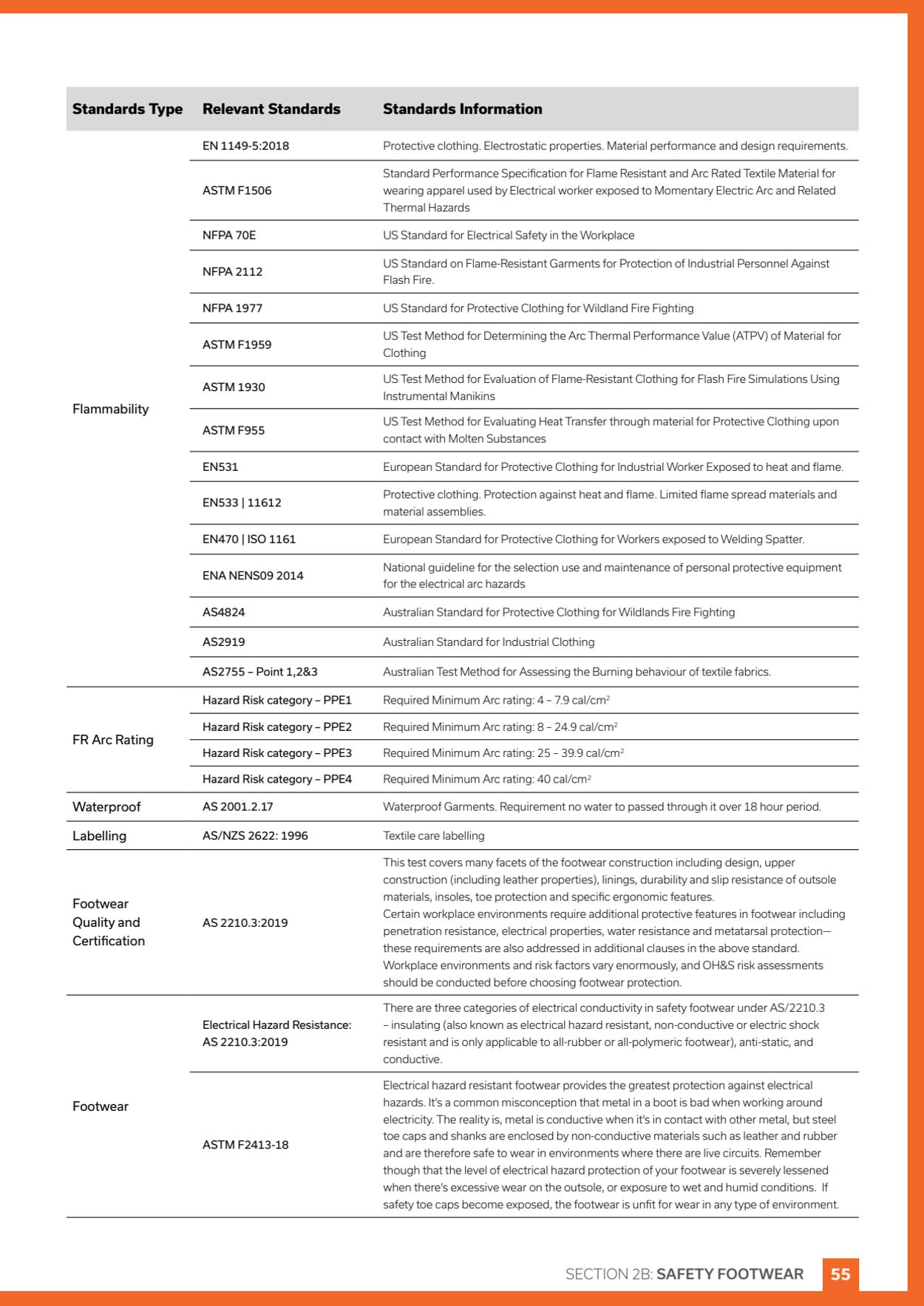

Standards Type Relevant Standards Standards Information EN 1149-5:2018 Protective clothing. Electrostatic properties. Material performance and design requirements. Standard Performance Specification for Flame Resistant and Arc Rated Textile Material for ASTMF1506 wearing apparel used by Electrical worker exposed to Momentary Electric Arc and Related ‘Thermal Hazards NFPA 70E US Standard for Electrical Safety in the Workplace NEPA 2112 US Standard on Flame-Resistant Garments for Protection of Industrial Personnel Against Flash Fire. NFPA 1977 US Standard for Protective Clothing for Wildland Fire Fighting US Test Method for Determining the Arc Thermal Performance Value (ATPV) of Material for ASTMF1959 ining Me (STEVE ‘ Clothing asniiess US Test Method for Evaluation of Flame-Resistant Clothing for Flash Fire Simulations Using Instrumental Manikins Flammability US Test Method for Evaluating Heat Transfer through material for Protective Clothing upon ASTM F955 contact with Molten Substances ENS31 European Standard for Protective Clothing for Industrial Worker Exposed to heat and flame. ensaa}21612 Protective clothing, Protection against heat and flame. Limited flame spread materials and material assemblies. EN470 | ISO 1161 European Standard for Protective Clothing for Workers exposed to Welding Spatter. ENANENSOSZOLa National guideline for the selection use and maintenance of personal protective equipment for the electrical arc hazards AS4824 Australian Standard for Protective Clothing for Wildlands Fire Fighting AS2919 Australian Standard for Industrial Clothing AS2755 - Point 1,283 Australian Test Method for Assessing the Burning behaviour of textile fabrics. Hazard Risk category-PPE1 Required Minimum Arc rating: 4 - 7.9 cal/em? Hazard Risk category-PPE2 Required Minimum Arc rating: 8 - 24.9 cal/em? FR Arc Rating Hazard Risk category-PPE3 Required Minimum Arc rating: 25 - 39.9 cal/em? Hazard Risk category-PPE4 Required Minimum Arc rating: 40 cal/cm? Waterproof AS 2001.2.17 Waterproof Garments. Requirement no water to passed through it over 18 hour period. Labelling AS/NZS 2622: 1996 Textile care labelling This test covers many facets of the footwear construction including design, upper construction (including leather properties), linings, durability and slip resistance of outsole Esotwear materials, insoles, toe protection and specific ergonomic features. Qisaliy and as ososui8 Certain workplace environments require additional protective features in footwear including Caraneati penetration resistance, electrical properties, water resistance and metatarsal protection— ertification these requirements are also addressed in additional clauses in the above standard. Workplace environments and risk factors vary enormously, and OH8S risk assessments should be conducted before choosing footwear protection There are three categories of electrical conductivity in safety footwear under AS/2210.3 Electrical Hazard Resistance: _— insulating (also known as electrical hazard resistant, non-conductive or electric shock AS 2210.3:2019 resistant and is only applicable to all-rubber or all-polymeric footwear), anti-static, and conductive Electrical hazard resistant footwear provides the greatest protection against electrical Foatwene hazards. It's a common misconception that metal in a boot is bad when working around electricity. The reality is, metal is conductive when it's in contact with other metal, but steel toe caps and shanks are enclosed by non-conductive materials such as leather and rubber ASTM F2413-18 e is and are therefore safe to wear in environments where there are live circuits. Remember though that the level of electrical hazard protection of your footwear is severely lessened when there's excessive wear on the outsole, or exposure to wet and humid conditions. If safety toe caps become exposed, the footwear is unfit for wear in any type of environment. SECTION 2B: SAFETY FOOTWEAR

| Name | Details |

|---|