Products in this catalogue

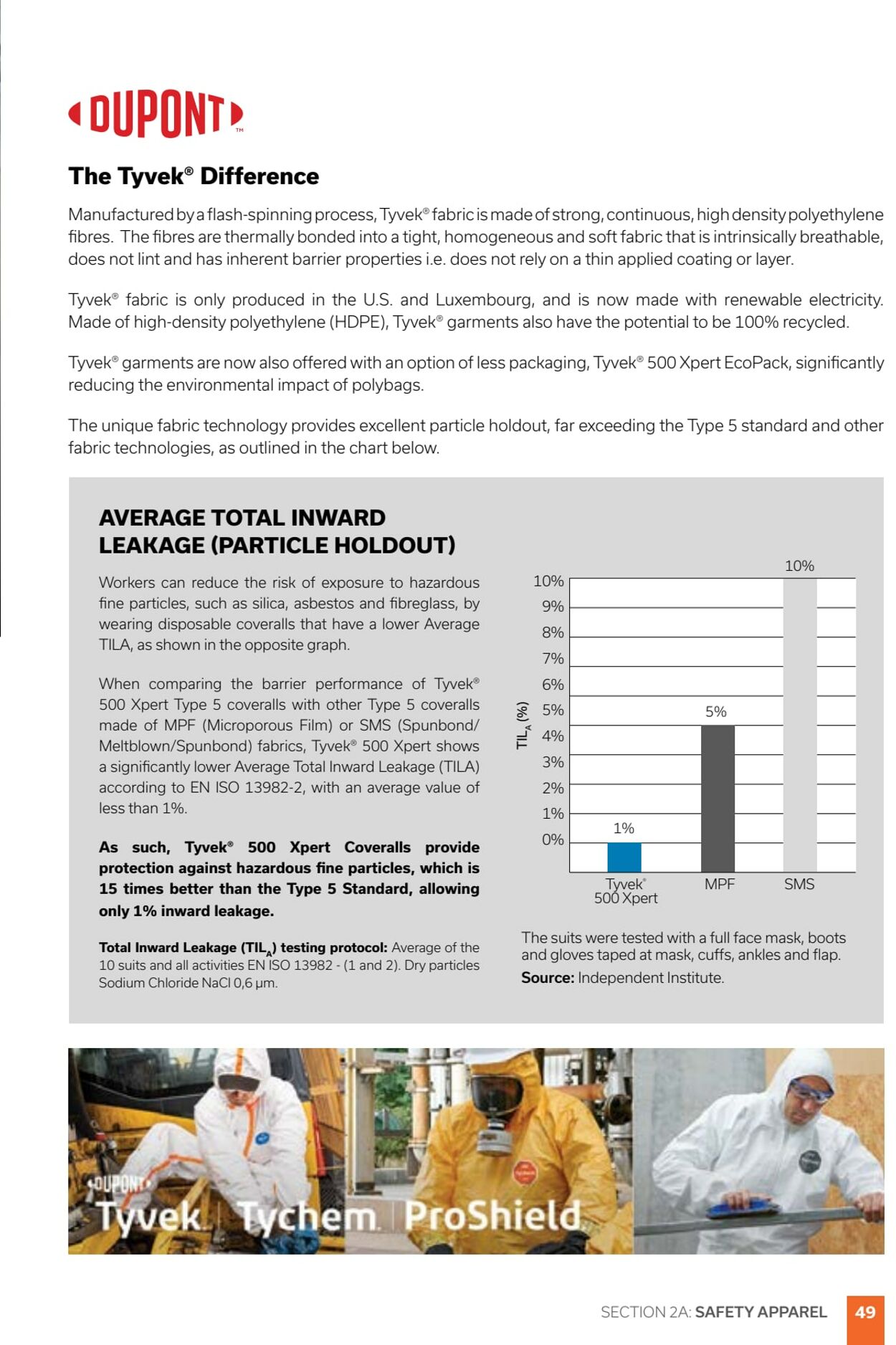

<OUPOQNT> The Tyvek® Difference Manufactured bya flash-spinning process, Tyvek® fabric is made of strong, continuous, high density polyethylene fibres. The fibres are thermally bonded into a tight, homogeneous and soft fabric that is intrinsically breathable, does not lint and has inherent barrier properties i.e. does not rely on a thin applied coating or layer. Tyvek® fabric is only produced in the U.S. and Luxembourg, and is now made with renewable electricity. Made of high-density polyethylene (HDPE), Tyvek® garments also have the potential to be 100% recycled. Tyvek® garments are now also offered with an option of less packaging, Tyvek® 500 Xpert EcoPack, significantly reducing the environmental impact of polybags. The unique fabric technology provides excellent particle holdout, far exceeding the Type 5 standard and other fabric technologies, as outlined in the chart below. AVERAGE TOTAL INWARD LEAKAGE (PARTICLE HOLDOUT) 10% Workers can reduce the risk of exposure to hazardous 10% fine particles, such as silica, asbestos and fibreglass, by Qm% |—__— |_| wearing disposable coveralls that have a lower Average 8% TILA, as shown in the opposite graph. Pe When comparing the barrier performance of Tyvek® 6% 500 Xpert Type 5 coveralls with other Type 5 coveralls g made of MPF (Microporous Film) or SMS (Spunbond/ << Meltblown/Spunbond) fabrics, Tyvek® 500 Xpert shows - a significantly lower Average Total Inward Leakage (TILA) according to EN ISO 13982-2, with an average value of less than 1%. 5% 5% As such, Tyvek® 500 Xpert Coveralls provide protection against hazardous fine particles, which is i i Tyvek’ MPF SMS 15 times better than the Type 5 Standard, allowing 500 Xpe a only 1% inward leakage. Total Inward Leakage (TIL,) testing p: EAvesceorte The suits were tested with a full face mask, boots 10 suits and all activities EN ISO 13982 - (1 and 2). Dry particles eo ee ae at ee Sodium Chloride NaCl 0,6 um. Source: Independent Institute. i, ) ens Ge an SECTION 2A: SAFETY APPAREL Rey

| Name | Details |

|---|